From raw materials to disposal-Numerous environmental measures and ingenuity of "ThinkPad"

From raw materials to disposal-Numerous images of environmental measures and ingenuity of "ThinkPad"

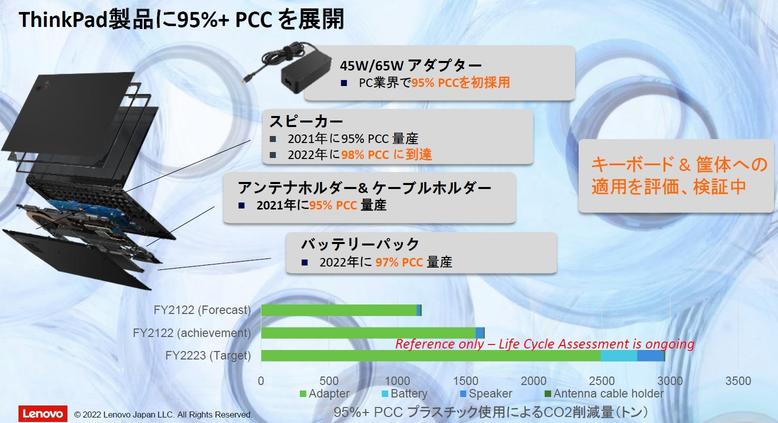

Lenovo Japan held a briefing on environmental initiatives in the creation of ThinkPad.Lenovo has a development base in Yamato Research Institute (Yokohama City) in Japan (Yokohama), North Carolina, USA, and Beijing, China, and has collectively referred to the "Innovation Triangle".Among them, Yamato Research Institute leads the development of notes PC ThinkPad and collaboration equipment "Thinksmart".Mr. Yasuori Tsukamoto of Distinguished Engineer, Executive Officer of Lenovo Japan Yamato Research Institute, "Focusing on" SMARTER TECHNOLOGY "to build a bright and sustainable future of the earth.The Yamato Research Institute also wants to use the power of making Japanese things in the world environment. "In the development of ThinkPad's product, the idea of "Think Green" is launched, and it is said that it is working on the environment from the perspective of the end -to -end from design, production, use and disposal.In the design, "design of environmental consideration" was implemented.We work on recycling materials (PCC), environmentally friendly materials, high power efficiency design, and reducing carbon dioxide emissions.Here, in collaboration with Sony Semiconductor Solutions, we introduced cases in which the company's environmental -friendly flame retarding plastic "SORPLAS" is used in ThinkPad.In 2017, Lenovo Japan started collaborating with Sony Semiconductor Solutions for the purpose of adopting a power adapter.In 2019, he acquired "UL (Underwriters Laboratories) certification" and shipped ThinkPad, which uses Sorplas from 2020.Commercial solution product development Commercial sub -system development Disting Disting Ished Engineer & Executive Director Madashi Kosuge said, "As of 2017, we shipped a power adapter that uses 30 % of resyclated materials, but 95 %.He succeeded in mass -producing through fine tuning of molds and improvements in injection molding in order to utilize high hurdles that exceeded. "In 2021, the industry adopted a plastic that satisfies ThinkPad's evaluation criteria and achieved a 95 % recycling material utilization."Other companies are only 50 %, and are expected to be about 80 % in 2023. There are more than three years of advantage than other companies."ThinkPad uses a power adapter, speaker unit, antenna holder, cable holder, and battery packs with more than 95 % recycled materials.In the future, he is considering applying to keyboard cover and housing, and wants to complete his technology within one year."ThinkPad has a very high quality standard because ThinkPad is characterized by its high robustness, because ThinkPad is characterized by its high robustness.We developed SORPLAS. In addition to high durability, adapters also support high impact strength. In speaker boxes, etc., we needed to respond to thin flesh structures, high flame retardant, and molded processing. These high quality standards.In terms of satisfaction, Renovo's optimization of molding conditions was also very effective. It has been a long -standing initiative since 2017, but it has finally been adopted for products in 2020. "Sony started the development of technologies that effectively utilize waste and waste liquids discharged from factories in 1995.In 2004, plastic chemicals were accidentally discovered that polycarbonate could give high flame retardancy, which led to the birth of Sorplas."By combining the unique flame-retardant additives" PSS-K ", we achieved a maximum of 99 % of high regenerative materials. The additives were provided in a small amount, maintaining the original characteristics of polycarbonate and high durability.It is SORPLAS that realized. Even after repeated melting mixed (operation to determine the physical properties of polymer material), it is also a major feature that it can maintain the initial properties, and can be reused and toned from the recovered ThinkPad.It is a high degree of freedom. It is a suitable technology for recycling, and I would like to consider recycling for more than 20 years in the future. "(Mr. Nakamura)It is said that engineering technology that can be prepared in a way can achieve various needs and quality that customers want.In addition, a simple manufacturing process leads to environmental contribution."Reduced about 75 % carbon dioxide emissions compared to flame -retardant virgin polycarbonate, contributing to Renovo's environmental impacting activities" (Nakamura) (Mr. Nakamura).

![[July 6 and 7] DX realized by content cloud, advanced platform for business transformation](https://website-google-hk.oss-cn-hongkong.aliyuncs.com/drawing/article_results_9/2022/3/9/6bbafe438d78271513761788166cbf94_0.jpeg)